SẢN PHẨM CÔNG NGHỆ

KUROSE SHELL & TUBE HEAT EXCHANGERS

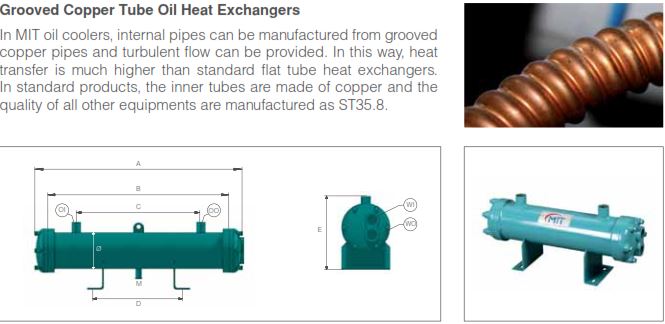

Oil Coolers

Many machines used in the industry need cooling during their work. The cooling process is usually caused by the collision of the water from the cooling tower or the chiller in the heat exchanger by the machine. KUROSE oil coolers can be used in all types of applications. Oil coolers can be manufactured as standard in certain dimensions and can be manufactured in special manufacturing processes.

| Model | Capacity | A | B | C | D | E | M | Ø | OI-OO | WI-WO | Weight |

| (Kcal/h) | (mm) | (mm) | (mm) | (mm) | (mm) | (inch) | (mm) | (inch) | (inch) | (kg) | |

| KUROSE.BYS.14.50 | 18100 | 590 | 500 | 340 | 340 | 252 | G 1/2″ | 140 | G 1″ | G 1″ | 29 |

| KUROSE.BYS.14.75 | 26400 | 840 | 750 | 550 | 500 | 252 | G 1/2″ | 140 | G 1″ | G 1″ | 32,5 |

| KUROSE.BYS.14.100 | 36300 | 1090 | 1000 | 800 | 650 | 252 | G 1/2″ | 140 | G 1″ | G 1″ | 42 |

| KUROSE.BYS.14.125 | 44500 | 1345 | 1250 | 1050 | 800 | 252 | G 1/2″ | 140 | G 1″ | G 1″ | 45 |

| KUROSE.BYS.16.50 | 21400 | 592 | 500 | 340 | 340 | 280 | G 1/2″ | 168 | G 1″ | G 1″ | 32 |

| KUROSE.BYS.16.75 | 34600 | 842 | 750 | 550 | 500 | 280 | G 1/2″ | 168 | G 1″ | G 1″ | 40 |

| KUROSE.BYS.16.100 | 44500 | 1092 | 1000 | 800 | 650 | 280 | G 1/2″ | 168 | G 1″ | G 1″ | 49 |

| KUROSE.BYS.16.125 | 56100 | 1342 | 1250 | 1050 | 800 | 298 | G 1/2″ | 168 | G 1″ | G 1″ | 57 |

| KUROSE.BYS.16.150 | 67600 | 1592 | 1500 | 1300 | 1000 | 292 | G 1/2″ | 168 | G 1″ | G 1″ | 66 |

| KUROSE.BYS.22.75 | 52800 | 850 | 750 | 550 | 500 | 349 | G 1/2″ | 220 | G 2″ | G 2″ | 66 |

| KUROSE.BYS.22.100 | 70900 | 1100 | 1000 | 800 | 650 | 349 | G 1/2″ | 220 | G 2″ | G 2″ | 77,5 |

| KUROSE.BYS.22.125 | 89100 | 1344 | 1250 | 1050 | 800 | 349 | G 1/2″ | 220 | G 2″ | G 2″ | 89 |

| KUROSE.BYS.22.150 | 107000 | 1594 | 1500 | 1300 | 1000 | 349 | G 1/2″ | 220 | G 2″ | G 2″ | 100 |

| KUROSE.BYS.22.175 | 125000 | 1844 | 1750 | 1550 | 1150 | 349 | G 1/2″ | 220 | G 2″ | G 2″ | 111 |

| KUROSE.BYS.22.200 | 143000 | 2094 | 2000 | 1780 | 1250 | 349 | G 1/2″ | 220 | G 2″ | G 2″ | 123 |

| KUROSE.BYS.22.250 | 179000 | 2594 | 2500 | 2280 | 1450 | 349 | G 1/2″ | 220 | G 2″ | G 2″ | 146 |

| KUROSE.BYS.25.75 | 92400 | 850 | 750 | 550 | 500 | 423 | G 1/2″ | 273 | G 2″ | G 2″ | 89 |

| KUROSE.BYS.25.100 | 123000 | 1100 | 1000 | 800 | 700 | 423 | G 1/2″ | 273 | G 2″ | G 2″ | 128 |

| KUROSE.BYS.25.125 | 165000 | 1350 | 1250 | 1050 | 800 | 423 | G 1/2″ | 273 | G 2″ | G 2″ | 145 |

| KUROSE.BYS.25.150 | 186000 | 1600 | 1500 | 1300 | 1000 | 423 | G 1/2″ | 273 | G 2″ | G 2″ | 162 |

| KUROSE.BYS.25.175 | 217000 | 1850 | 1750 | 1550 | 1150 | 423 | G 1/2″ | 273 | G 2″ | G 2″ | 180 |

| KUROSE.BYS.25.200 | 247000 | 2100 | 2000 | 1780 | 1250 | 423 | G 1/2″ | 273 | G 2″ | G 2″ | 197 |

| KUROSE.BYS.25.250 | 310000 | 2600 | 2500 | 2280 | 1450 | 423 | G 1/2″ | 273 | G 2″ | G 2″ | 230 |

| KUROSE.BYS.25.300 | 371000 | 3100 | 3000 | 2760 | 1700 | 423 | G 1/2″ | 273 | G 2″ | G 2″ | 263 |

Shell And Tube Heat Exchangers With Finned Tube

The heat exchangers with flap heating surfaces, which are called laminated pipe heat exchangers, significantly increase the heat transfer between gases and liquids, saving space and are more efficient than flat pipes.

MIT laminated pipe heat exchanger is used in many different applications in industry. It allows heat transfer up to 1000 kW capacity.

Advantages

- Heat transfer surface between

0.43 m2 and 56 m2.

- Corrosion resistant, aluminum lamellae that increase the heat transfer area.

- Heat transfer up to 1000 kW.

- 1500 liter / minute oil flow rate.

- Detachable cap and tube bundle make it possible to clean the heat exchanger.

| Model | A | B | F | Q | m2 | Weight (kg) |

| KFYS-505 | 189 | 55 | G 3/4″ | Ø 9 x 16 | 0,43 | 3,15 |

| KFYS-508 | 265 | 97 | G 3/4″ | Ø 9 x 16 | 0,73 | 3,60 |

| KFYS-510 | 316 | 148 | G 3/4″ | Ø 9 x 16 | 0,94 | 3,45 |

| KFYS-512 | 367 | 199 | G 3/4″ | Ø 9 x 16 | 1,13 | 4,05 |

| KFYS-514 | 418 | 250 | G 3/4″ | Ø 9 x 16 | 1,43 | 4,50 |

| KFYS-518 | 519 | 351 | G 3/4″ | Ø 9 x 16 | 1,74 | 5,10 |

| KFYS-524 | 672 | 504 | G 3/4″ | Ø 9 x 16 | 2,35 | 6,00 |

| KFYS-536 | 976 | 808 | G 3/4″ | Ø 9 x 16 | 3,57 | 7,80 |

| KFYS-708 | 283 | 76 | G 11/2″ | Ø 11 x 19 | 1,38 | 7,30 |

| KFYS-712 | 385 | 178 | G 11/2″ | Ø 11 x 19 | 2,18 | 8,40 |

| KFYS-714 | 436 | 229 | G 11/2″ | Ø 11 x 19 | 2,53 | 8,80 |

| KFYS-718 | 537 | 330 | G 11/2″ | Ø 11 x 19 | 3,29 | 10,20 |

| KFYS-724 | 690 | 483 | G 11/2″ | Ø 11 x 19 | 4,44 | 11,60 |

| KFYS-736 | 976 | 787 | G 11/2″ | Ø 11 x 19 | 6,73 | 15,50 |

| KFYS-1012 | 397 | 157 | G 11/2″ | Ø 11 x 25 | 4,38 | 15,40 |

| KFYS-1014 | 448 | 208 | G 11/2″ | Ø 11 x 25 | 5,17 | 16,90 |

| KFYS-1018 | 549 | 309 | G 11/2″ | Ø 11 x 25 | 6,73 | 19,80 |

| KFYS-1024 | 702 | 462 | G 11/2″ | Ø 11 x 25 | 9,06 | 21,80 |

| KFYS-1036 | 1006 | 766 | G 11/2″ | Ø 11 x 25 | 13,74 | 30,50 |

| KFYS-1048 | 1307 | 1067 | G 11/2″ | Ø 11 x 25 | 18,41 | 39,80 |